Search

THE FRENCH GAME works with post-war workshops that have passed on their know-how from generation to generation to bring you quality products that stand the test of time.

LEATHER

THE SEARCH? The Lyon region is home to some of the finest leatherworkers in the world. The grandfather of our current bretellier-ceinturier chose this region to set up his first workshop in the 1950s after the Second World War. By word of mouth, we heard about his reputation. We've been working with him since 2017.

WOMEN AND MEN? This workshop, founded in the 1950s, has around twenty year-round employees. Those closest to retirement often worked for the founding grandfather. An entire career in the same workshop! That says a lot about the working conditions and atmosphere here.

THE RAW MATERIAL? The leather and split leather used here come from French and German cows. They are selected for their resistance and durability. Each hide is identified to ensure rigorous traceability.

WEAVING

THE SEARCH? It was at a manufacturers' trade show that we met our French weaver of exceptional craftsmanship. Based in the Saint-Etienne region, it was created by the great-grandfather of the current founder in the 1950s.

WOMEN AND MEN? A dozen people work year-round on the looms of this family-run workshop in the Saint-Etienne region. Labels are applied by seamstresses working at home on their own machines. This workshop is a major source of employment for the nearby town of 6000 inhabitants.

THE RAW MATERIAL? Our stoles are made from microfibres. This synthetic material is silky to the touch and highly resistant. In particular, it prevents "pilling" over time.

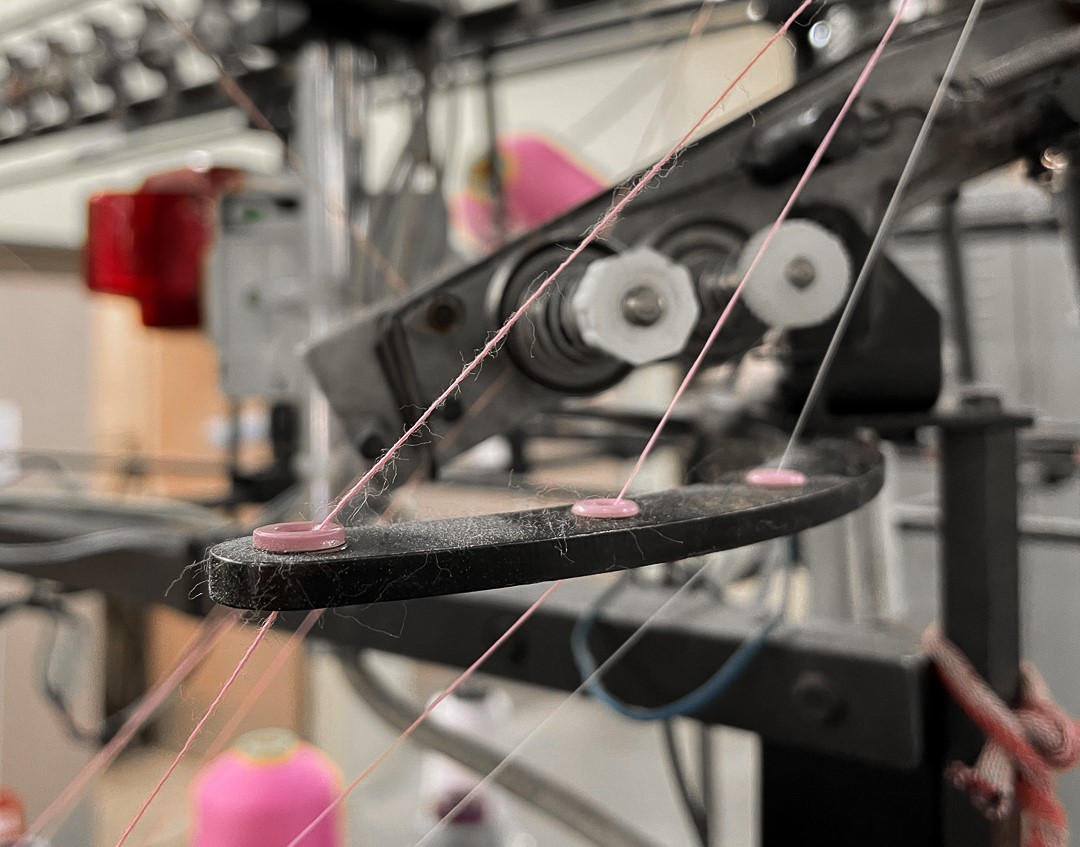

COTTON

THE SEARCH? The Troyes region is famous for its bonneteries (a term given to sock manufacturers). In the 1950s, it was an important area for the textile industry. My research naturally led me to one of Troyes' finest shoemakers.

WOMEN AND MEN? Women and men working in the hosiery industry are responsible for supervising the machines that knit socks. They load the bobbins of yarn, and take care of laying the cardboard wrapping that joins the two socks together, known as the "jumper". The workshop operates on a "2x8" basis, i.e. with two shifts: one in the morning and one in the evening.

THE RAW MATERIAL? We use top-quality Italian and Portuguese cotton. This cotton is "OEKO-TEX" certified, i.e. free of substances harmful to people and the environment. This cotton has been "combed" to retain only the longest, highest-quality fibers. This ensures unparalleled comfort when worn. This type of cotton is called "combed cotton", as opposed to uncombed or "carded" cotton.

GRAPE

THE SEARCH? It was while we were looking for a substitute for animal-based leather that we discovered there was a grape-based alternative. We discovered that in Italy's Lombardy region, there was the first innovative company capable of synthesizing this material.

WOMEN AND MEN? The grape-based material we use as an alternative to leather was developed by a laboratory of "chemist-farmers" in Italy in 2016.

THE RAW MATERIAL? This plant-based alternative to leather is derived from the waste products of the wine-making process. Grapes, skins and seeds are crushed and then mixed with a vegetable oil. The resulting bio-compound is spread on a weft of recycled fabric. Abrasion, tearing, disgorgement: the resulting material has successfully passed all ISO quality tests for leather of animal origin.